CDR News

S&P with a new report that mentions the need for removals

An expose with the founder of a carbon removal startup

Nerd rating: 8 (1 to 10 scale on the technical density of the post)

Removing Carbon

This piece will dive deeper into direct air capture and the “sponge” like technologies that remove carbon from the atmosphere. And to start, I’d like to take one giant step back.

Ambient air must come in context with the solid sorbent or liquid solvent for the chemistry to occur. This seems obvious, and it is, but it is a critical energetic step in the process. There is a considerable amount of variation within the space.

Climeworks “sucks” the air into the contactor through a fan like the picture below. We can think of this more as an active process.

This model can regulate and modulate the amount of air taken in; however, it does use more electricity than passive air contactors. Depending on the scale, this difference can be in the millions of dollars.

Passive contacting is just as the name suggests, allowing ambient air to flow over the sorbent for contact naturally. This is the approach taken by Carbon Collect, Infinitree, and Heirloom. Yet another approach uses existing infrastructure, like air and liquid flow through cooling towers, to lower the cost of contacting. Noya takes this approach.

So from a process level, you can either pull the air in, let it naturally come in contact, or hook into existing fluid flow systems to minimize the energy and capital costs that come with building fans. However, once the air is in, it will hit the contactor, filled with the solvent or sorbent. The diagrams below provide a high-level look at those processes.

Solvent System Diagram

Solid Sorbent Diagram

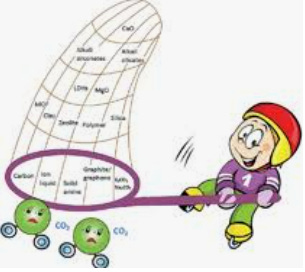

Generally speaking, solid sorbents can take the form of metal-organic frameworks (MOFs), sieves, zeolites, and porous natural materials. These structures and chemistries constantly evolve as more research and innovation happens within the space. Once the air comes in contact with the sorbent material, the carbon dioxide bonds to that material while the other molecules present in the air pass through the “sponge” some technologies, like Climeworks, use amine-functionalized filters, these filters increase the number of interactions that carbon dioxide has with the filters. The more interactions a filter may have with the carbon dioxide, the more binding to the solid sorbent.

Liquid solvents rely on the carbon being absorbed into the solvent. This creates a carbon-rich solvent. Packing these solvents is frequent to increase the surface area available for contact1. Skipping over a few highly technical steps here for brevity and sanity. Out of this carbon-rich solvent fluid, calcium carbonate pellets are produced. A high-temperature influx is needed to harvest the carbon dioxide from these pellets. However, high temperature is not a feature unique to the solvent approach.

Both the solid sorbent and liquid solvent DAC approaches require roughly 80% thermal energy and 20% electricity for operation [32]. This is not an arbitrary percentage as both DAC approaches must optimize between a multitude of parameters. In both systems, the thermal energy demand results from the regeneration of the sorbent and the evolution of the previously bound CO2 compounds. For the solid sorbent approach, the electricity requirements result from the contactor fans, which are required to overcome the system pressure drop, and the vacuum pumps, which remove residual air from the contactor during regeneration [2]. The liquid solvent system requires electricity for the contactor fans—also required to overcome the system pressure drop—as well as the pellet reactors, steam slaker and filtration units [17]. Both approaches must optimize between the pressure drop across the contactor and the amount of CO2 removed from the inlet air stream. This optimization determines parameters like the electricity required to power fans to overcome this pressure drop.

The above quote is from “A review of direct air capture (DAC): scaling up commercial technologies and innovating for the future Noah McQueen et al 2021 Prog. Energy 3 032001”. I suggest every reader look over this paper. It presents the state-of-play for direct air capture technology in a technically dense but approachable fashion. I use it frequently.

Driving down the electricity and thermal costs of DAC systems is key to the overall price of capture coming down, alongside the increasing modularity of the systems. Modularity, and its importance, which we will touch on in the coming weeks.

After the carbon is captured within whatever medium, that carbon must be released, and then the sorbent/solvent regenerated to receive the subsequent influx of air. This step, known as regeneration, has three main pathways: temperature swing, pressure swing, and electrochemical swing. We will explore these in the next post.

The below information is taken from last week’s blog as it was germane to this post.

Solid Sorbents

Solid sorbents include a wide variety of physical chemistries to capture the CO2

Benefits of Solid sorbent designs1

Offer the possibility of low energy input

Low operating costs and applicability across a wide range of scales

Challenges of solid sorbent designs2

The need to build a substantial structure at low cost while allowing the entire structure to be periodically sealed from the ambient air during the regeneration step when temperature, pressure, or humidity must be cycled.

The inherently conflicting demands of high sorbent performance, low cost, and prolonged economic life in impure ambient air.

A notable chemical structure in this space are Metal-Organic Frameworks (MOFs)

Benefits include

Challenges

Commercial production of MOFs

Availability of metals for production

Liquid Solvents

Liquid solvents are used less than solid sorbents and come with their host of benefits and challenges.

Benefits of Aqueous sorbents

The contactor can operate continuously

Can be built using cheap cooling-tower hardware

The (liquid) surface is continuously renewed, allowing very long contactor lifetimes despite the dust and atmospheric contaminants.

Once captured, CO2 can be easily pumped to a central regeneration facility allowing economies of scale and avoiding the need to cycle conditions in the inherently large air contactor.

Challenges of Aqueous sorbents

Cost and complexity of the regeneration system

Water loss in dry environments.

Benchmarking

Crawling through various scientific publications, media clips, interviews, and websites, I compiled a non-exhaustive list of DAC companies and the various liquid solvent and solid sorbents they use to achieve removal. I added notes around what differentiates their air intake method when possible.

Given some feedback from several readers. I will continue to benchmark these differentiating qualities between companies and put them into a post as needed. For instance, I’ll be looking at modularity in a couple of weeks and will note which companies employ that strategy.

Liquid Solvent Companies2

Carbon Engineering

Potassium hydroxide solution/calcium carbonation

Fan driven contact

Noya

Undisclosed solvent

Co-opted contact from cooling towers

Mission Zero

Undisclosed non-hydroxide solvent

Contact unclear, but given it’s a liquid solvent, I’m guessing fan driven

1point5

Undisclosed solvent

Fan driven contact

Solid Sorbent Companies3

Climeworks

Amine-functionalized filter

Fan drive contact

Global Thermostat

Amine-modified monolith

Fan driven contact

Infinitree

Ion-exchange sorbent

Passive driven contact

Skytree

Porous plastic beads functionalized with benzylamines

Passive driven contact

Heirloom

Magnesium or calcium oxides in contact with ambient air (which flows through air contactors)

Passive driven contact

Carbon Collect

Solid Sorbent from Silicon Kingdom

Passive contact

Carbon Capture

Active contact

Sustaera

Alki-metal based

Fan driven contact

Verdox

Stacked electrochemical cells

Fan driven contact

Carbon infinity

Metal-organic framework

Fan driven contact

8 Rivers

Calcium oxide as a solid sorbent

Warehouse based contactors - unclear if this is dovetailing on the warehouse system like Noya or something different

Next week: Tech Deep Dive: Direct Air Capture 3 - regeneration mechanisms

Learn

Third Derivative out with a new report

Follow

https://twitter.com/rorypjacobson for policy and memes

https://twitter.com/ErinBakerEnergy Academic Excellence

https://mobile.twitter.com/noya_carbon is an innovative startup

Holmes G and Keith D W 2012 An air-liquid contactor for large-scale capture of CO2 from air Phil. Trans. R. Soc. A 370 4380–403

https://www.nap.edu/read/25259/chapter/7#192

https://www.nap.edu/read/25259/chapter/7#192