CDR News

A DAC company gets some serious cash backing

DAC on offshore wind turbines? Maybe, maybe not.

Europe reiterating that the quality of removals matters - this isn’t your dad’s commodity market

Nerd rating: 5 (1 to 10 scale on the technical density of the post)

What is Direct Air Capture?

Direct Air Capture (DAC) is an appropriate name given it describes precisely how the technology functions.

I have some personal reservations about the term “capture” and think we should instead use Direct Air Removals. As I have previously written, the world “capture” is associated with carbon capture and sequestration. This technology reduces current emissions from a concentrated flue stream. Direct Air Capture removes legacy emissions from a diffuse source, the ambient air. Both are important for net-zero futures, but they have distinct histories, technologies, and, thus, policy prescriptions.

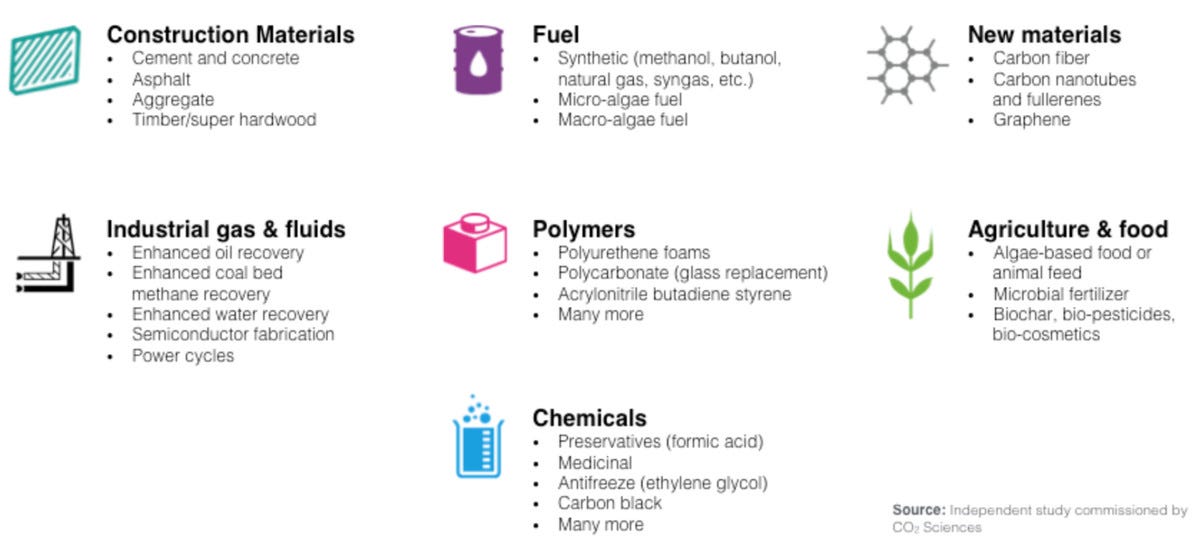

DAC encompasses several different operations that fundamentally accomplish the same goal: capturing and removing carbon dioxide from the ambient air. Colloquially, sucking the carbon right out of the air. This pure carbon dioxide stream is then either sequestered underground for permanent storage or used in various applications: greenhouses, soda carbonation, cement, fuel feedstock.

Mechanisms

Capturing the CO2 from the air and then releasing it to be used or stored can be viewed through the analogy of a sponge. This sponge has a liquid pass through it that contains many different chemical structures. We want a sponge that captures the carbon dioxide and allows you to “squeeze” out all the carbon to be stored or used. A filter is another oft-used analogy.

In this case, the sponge aspect of the technology encompasses two primary flavors: solid and liquid sorbents.

Solid Sorbents

Solid sorbents include a wide variety of physical chemistries to capture the CO2

Benefits of Solid sorbent designs1

Offer the possibility of low energy input

Low operating costs and applicability across a wide range of scales

Challenges of solid sorbent designs2

The need to build a substantial structure at low cost while allowing the entire structure to be periodically sealed from the ambient air during the regeneration step when temperature, pressure, or humidity must be cycled.

The inherently conflicting demands of high sorbent performance, low cost, and long economic life in impure ambient air.

A notable chemical structure in this space are Metal-Organic Frameworks (MOFs)

Benefits include

Challenges

Commercial production of MOFs

Availability of metals for production

Aqueous Basic Solutions3

Benefits of Aqueous sorbents

The contactor can operate continuously

Can be built using cheap cooling-tower hardware

The (liquid) surface is continuously renewed allowing very long contactor lifetimes despite dust and atmospheric contaminants

Once captured, CO2 can be easily pumped to a central regeneration facility allowing economies of scale and avoiding the need to cycle conditions in the inherently large air contactor.

Challenges of Aqueous sorbents

Cost and complexity of the regeneration system w

Water loss in dry environments.

Now that a DAC facility has used one of the two technologies above, they must “squeeze” the sponge to release the CO2 and regenerate the sponge so it can soak up another round of CO2. This is a critical step in cost control.

There are three primary release pathways:

Temperature swing

Rapidly changing (increasing) the temperature to break the chemical bond between “sponge” and carbon dioxide molecules

Pressure swing

Rapidly changing the pressure in the “sponge” to release carbon dioxide molecules

Electro-potential swing

Using electrochemical mediation through oxidized displacers or sorbents to break the bond between “sponge” and carbon dioxide molecules

The totality of the process is a constant iteration of filling up the sponge and squeezing the CO2 out. Two diagrams below for the visual learners note that in each of these, they heat the filter. This is a temperature swing and could also be done through pressure changes or electro-potential

or another way

Usage or storage

After the carbon dioxide is captured, it is now up for storage or usage. It can be stored in the subsurface in saline aquifers, depleted oil and gas wells, coal seams, basalt lithologies, etc.

As of now, there are very few storage efforts underway outside of the Climeworks plant in Iceland. This is fundamentally due to the lack of revenue and incentive to store carbon without a carbon price. Another end-use of carbon dioxide is in products.

Major players

There are the three big or initial players in the DAC space:

Each of these companies has its blend of sponge and release technologies and chemistries that they find particularly conducive. I’ll highlight some of these in later deep dives.

However, a growing number of companies are entering the space with new capture and release technologies, business models, and modularity options.

I am not going to re-create the wheel. Check out this post by fellow CDR enthusiast Na’im Merchant for the bleeding edge of carbon capture.

Next week: Tech Deep Dive: Direct Air Capture 2 - capture mechanisms

Learn

Why is basalt the hottest rock in sequestration?

Follow

https://twitter.com/XanFishman for policy and memes

https://twitter.com/JesseJenkins Academic Excellence

https://twitter.com/VerdoxCC an innovative startup

https://www.sciencedirect.com/science/article/pii/S2542435118302253#bib21

https://www.sciencedirect.com/science/article/pii/S2542435118302253#bib21

https://www.sciencedirect.com/science/article/pii/S2542435118302253#bib21