Tech Deep Dive

Direct Air Capture - Regeneration Mechanisms

CDR News

WaPo on why we need more investment

National Academies discusses Ocean CDR

Huge White House announcement that hits on removals, amongst other things

Nerd rating: 7 (1 to 10 scale on the technical density of the post)

Regeneration

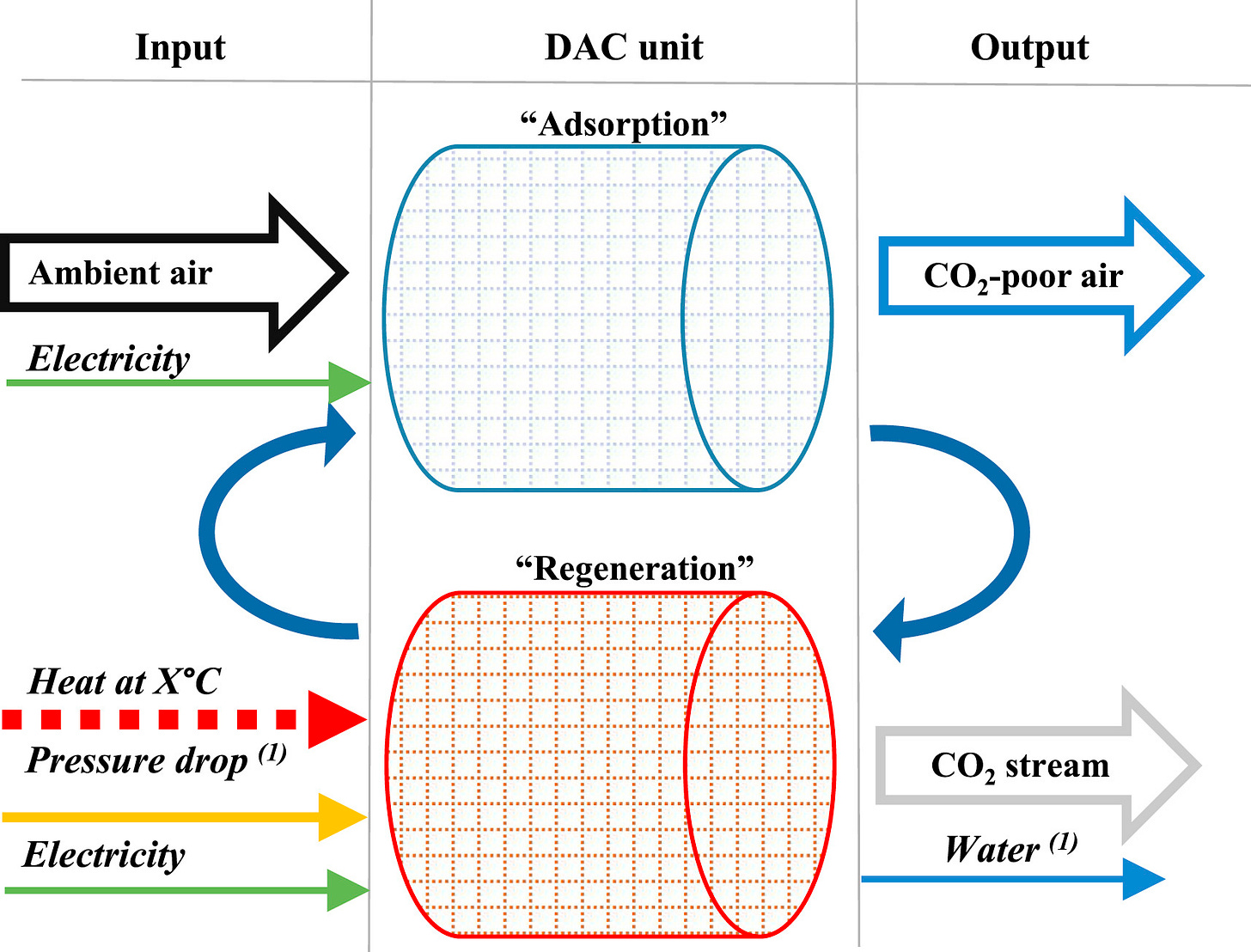

Last week we covered the in-take methods (active/fan/existing airflow vs. passive) as well as the capture mechanisms (liquid solvent vs. solid sorbent). This covers two essential processes within the DAC system. Today we will cover the third: regeneration.

In keeping with the analogy of a sponge, the system first soaks up the carbon dioxide and lets other chemical constituents pass through. Then, the sponge must release these carbon dioxide molecules, ideally, as a pure carbon dioxide stream. This allows for the carbon dioxide to be stored or utilized and allows the solvent/sorbent to be used again.

Fundamentally there are two buckets for regeneration: temperature-pressure swing electrochemical swing. These all refer to a “swing” or a rapid change in the preceding noun to trigger the release of the carbon dioxide molecules.

Temperature-pressure swing

I have lumped temperature and pressure together in a single swing for simplicities sake. As previously mentioned in this substack, one main difference between liquid solvents and solid sorbents is the regeneration temperature needed. Liquid solvents will require much higher temperatures (>900 C) as opposed to solid sorbents (>100 C). These low-heat or waste heat solid sorbents will often combine that heat with a vacuum or pressure swing to release the carbon dioxide, as is the case with Climeworks and Global Thermostat. However, this vacuum swing can be utilized in high heat processes like CarbonCapture, which uses high heat vacuum swings with their zeolite-based sorbents.

Mineralization techniques like heirloom also use high-temperature swings for their regeneration.

In all cases, the combination of heat and pressure breaks the bonds between the carbon dioxide and the solvent/sorbent, allowing for a carbon dioxide stream to leave as an output and the solvent/sorbent to be regenerated for the following input of ambient air.

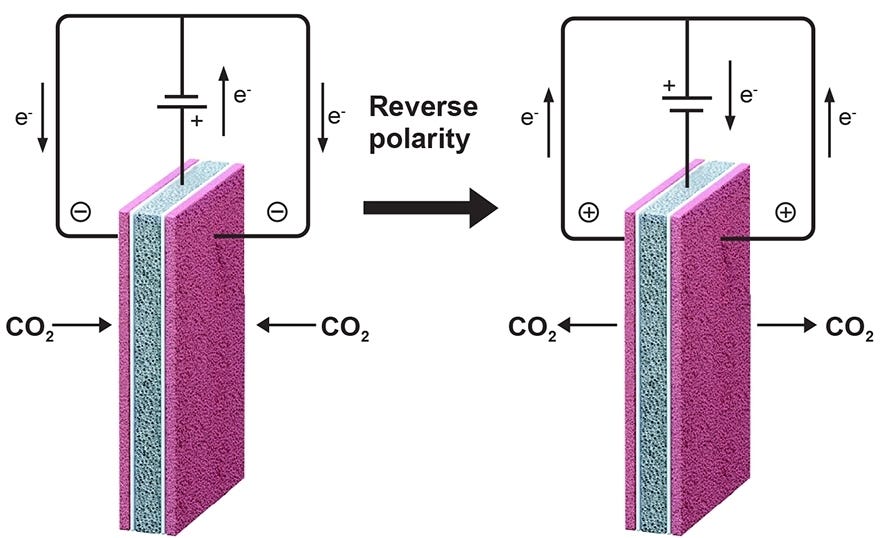

Electrochemical swing

A much more nascent technology is the electrochemical swing. This process uses electricity, ideally renewable, to trigger chemical reactions which can capture the carbon and then be reversed or deactivated to release.

Two buckets within the electrochemical swing are actively being studied

pH-swing

In a liquid solvent, carbon dioxide is captured and then recovered using electricity to manipulate the pH. The electricity works through this solvent, changing the pH from basic to acidic and back again. Heimdal is proposing, with their liquid solvent being seawater.

Redox carriers

Like the newly funded startup Verdox, Redox carriers have been exploring displacement release or activated capture release. This technique uses oxidation and reduction reactions that are electrochemically dictated to either capture or release carbon dioxide. In the case of the displacement release, the solid sorbent is exposed to an oxidized replacer, releasing carbon dioxide. Then in the regeneration phase, that same sorbent is reduced, allowing it to receive carbon dioxide again. The entire sorbent is oxidized in the activated capture release version, releasing carbon dioxide and then reducing during regeneration.

Source

Around the 15-minute mark, this video provides an excellent explanation and visual of this process.

Next week: Tech Deep Dive: Direct Air Capture 4 Technoeconomics and final thoughts

Learn

A paper on scaling DAC solutions

Follow

https://twitter.com/jasonclimateguy for all things DAC

https://twitter.com/leahstokes Academic Excellence

https://twitter.com/NetZeroTom founder of an innovative startup